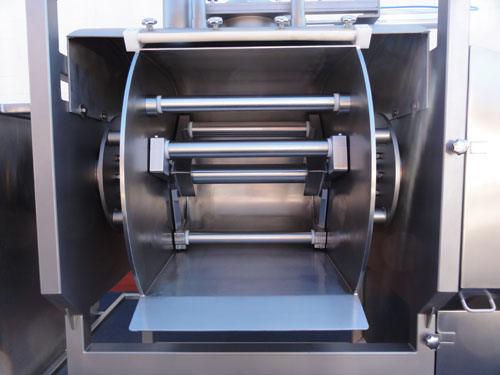

Topos Mondial Corp designs and manufactures heavy-duty, open-frame, three-roller bar horizontal dough mixers (OFRBHM) in sizes 4, 6, and 8, with dough mixing capacities ranging from 400 to 800 lbs. These mixers feature a rugged open-frame sanitary design that simplifies cleaning and maintenance. Customers can select frames made from heavy-duty mild steel with “Steel-It” S/S coating or stainless steel for maximum durability.

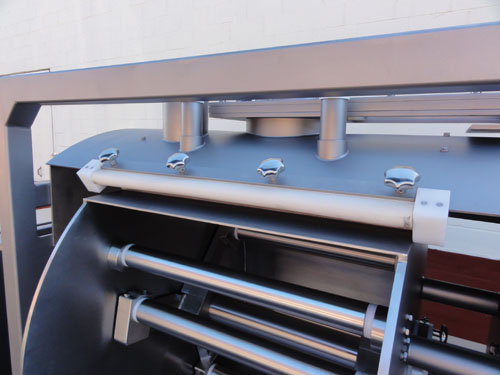

A powerful SEW hollow shaft direct drive gear-motor drives the main agitator, offering options for VFD ratings or two-speed functionality. The stainless steel cover protects the drive gear-motor and hydraulic package while allowing tool-free removal for easy access.

Topos equips the mixing bowl with an adjustable roller bar and stretcher bar position for optimal performance. A self-contained Hytos hydraulic package with a manual hand pump operates the hydraulic over-tilt bowl assembly. For enhanced cooling, the bowl can include a jacket and insulation, along with easy-to-clean main shaft seals and removable bowl-to-canopy seals.

With a unique bowl shape and roller bar positioning, these mixers shorten mixing times, lower agitator speeds, and reduce overall energy consumption. Topos’s OFRBHM mixers deliver unmatched performance, durability, and value.

Made by: Topos Mondial Corp

Quantity Available: Made to order

Request a Quote

Download Brochure