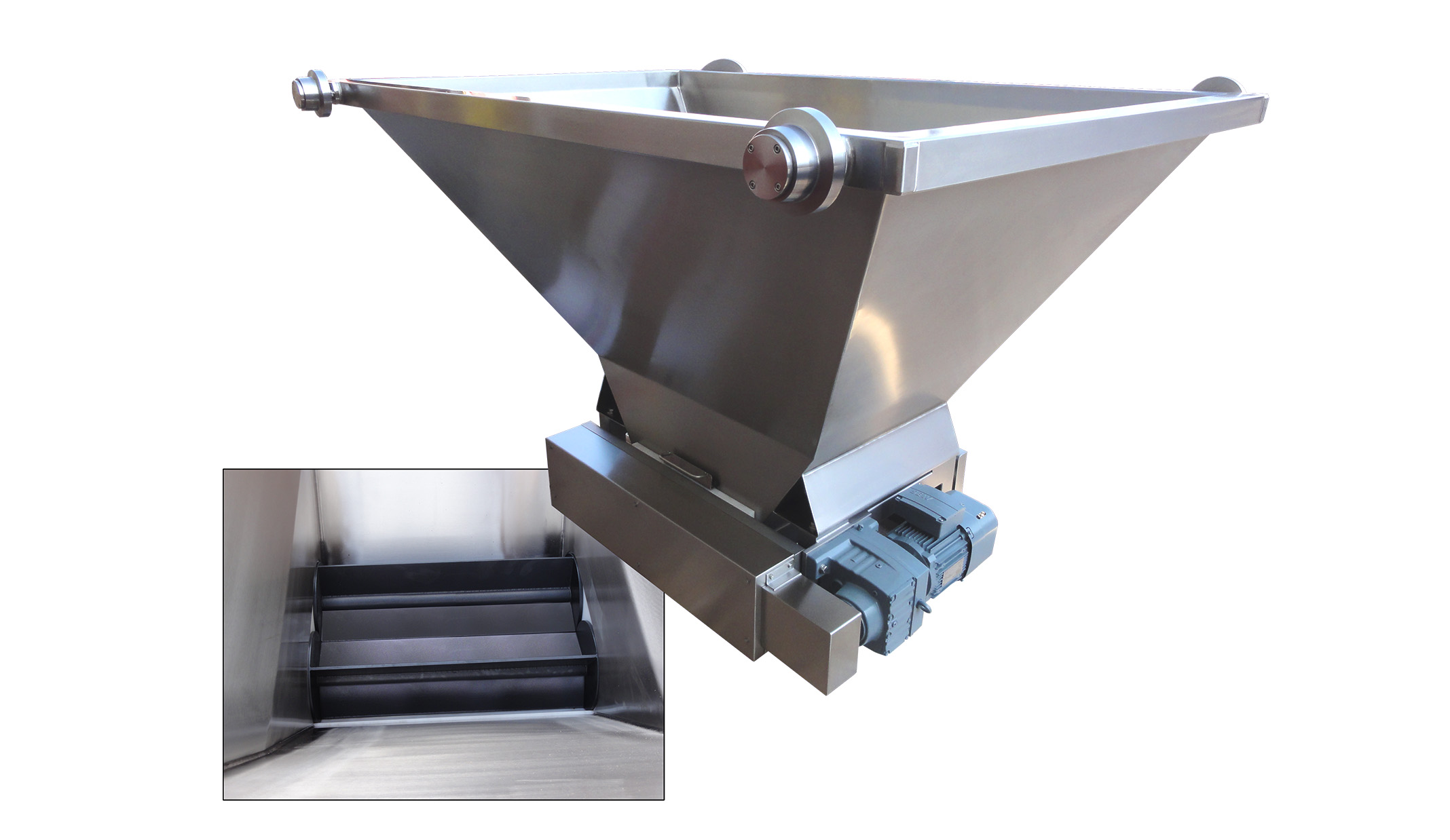

Topos offers a variety of Overhead Dough Chunker (OHDC) for partitioning dough into a divider, a dough extruder, or a primary dough feeder.

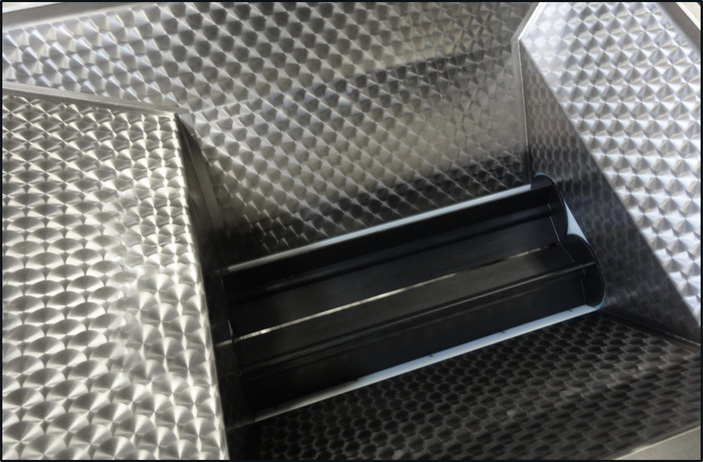

Topos can customize the hopper size and the support structure to meet your plant layout and production needs. The dough chunker utilizes a pair of proven triad type chunking blades. The blades are Teflon coated as standard and the hoppers can be Teflon coated [optional] to suit as needed. The chunking hoppers can be made either stationary or mobile on top of the supporting stand to give access to the divider or the extruder under it. Optional operator platforms are also available for personnel access to the inside of the hoppers. The systems are built in all stainless steel and offer advanced programmable controls as needed.

Request a Quote

Download Brochure