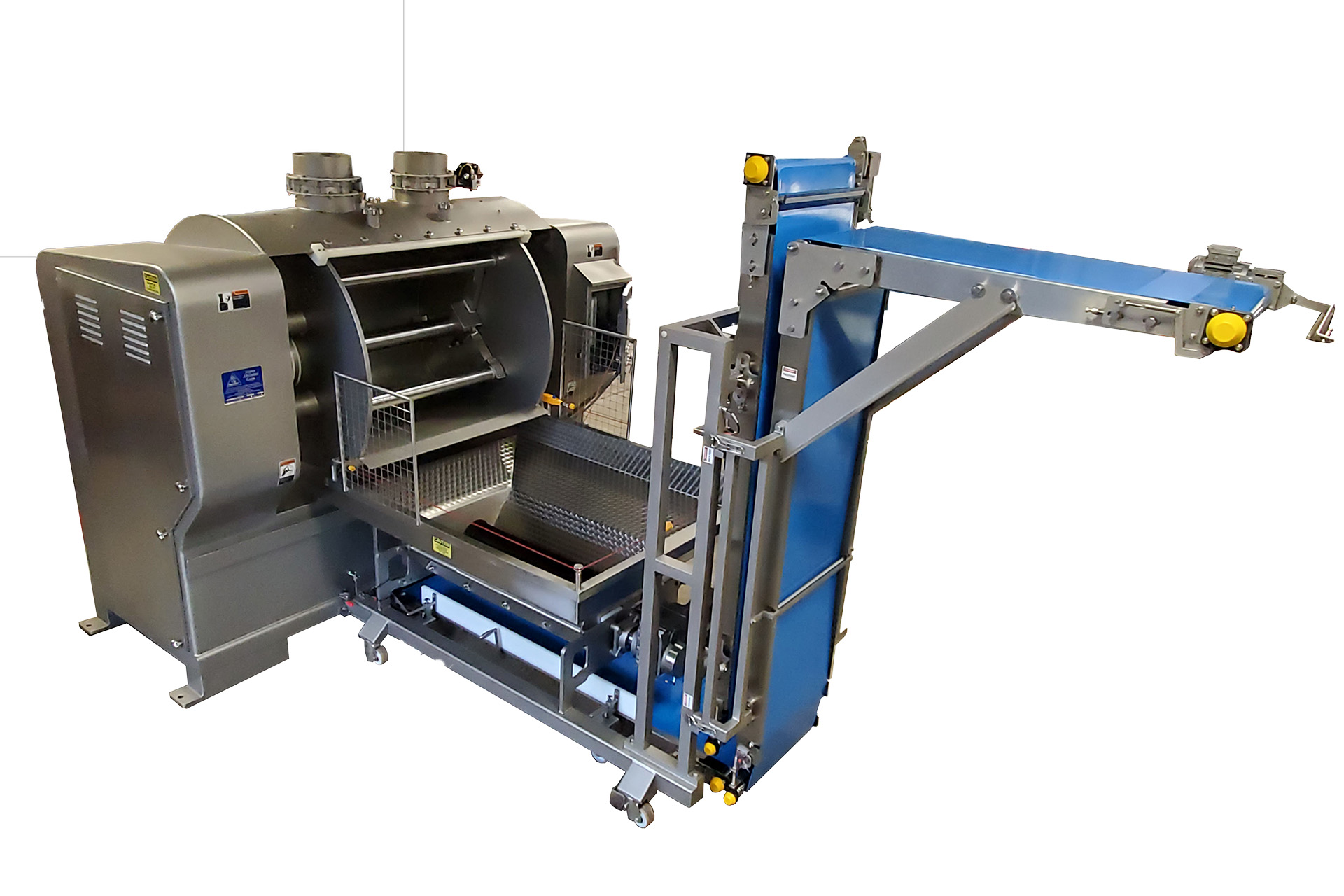

Topos Mondial Corp offers dough chunkers and elevators (TDCE) with hopper capacities ranging from 1,000 lbs to 3,000 lbs. These systems can chunk up to 20,000 lbs of dough per hour. The chunker works with a twin-belted dough elevator, custom-built to fit your needs.

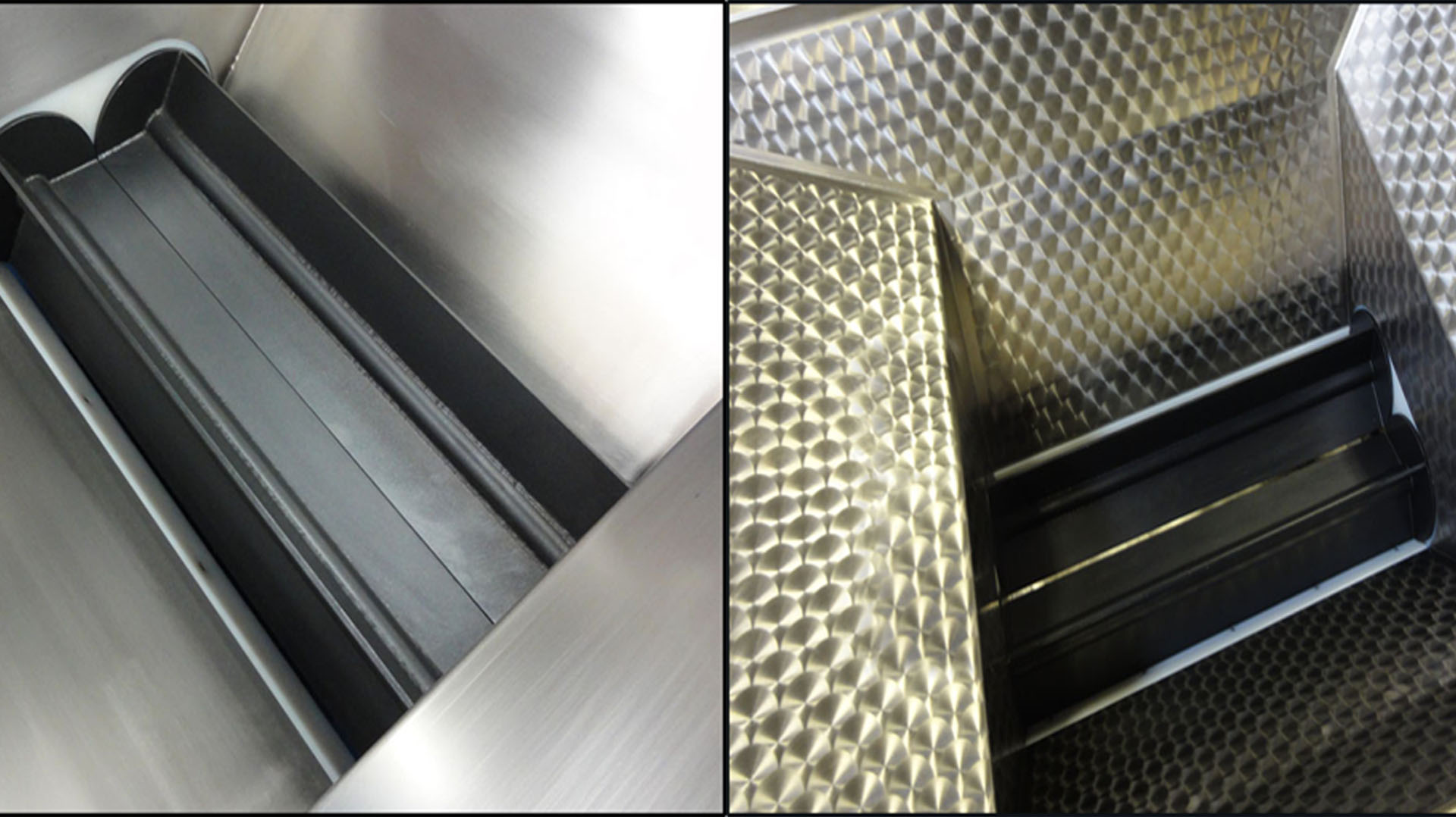

The 29” to 59” long “Triad” chunking blades break the dough onto the horizontal belt, feeding it into the elevator. Key features include non-stick coated blades, stainless steel sanitary construction, quick-release belts for easy cleaning, and optional PLC controls. Secondary feeding belts can be customized to transfer dough from the elevator discharge to any location in your production area.

Made by: Topos Mondial Corp

Quantity Available: Made to order

Request a Quote

Download Brochure